Work preparation / material development

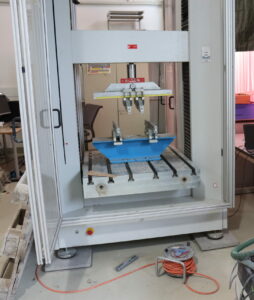

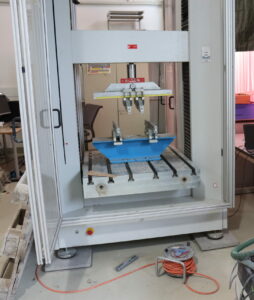

Carrying out the experiment

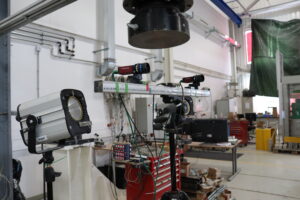

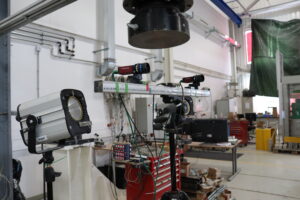

Measurement technology and special equipment

Measurement technology and special equipment